EPS Insulated Render System

Engineering Bulletin 071 - Insulated Render Systems With Combustible Insulation contains considerations and practical guidance and on use of fire barriers, and fixings in insulated render facades. The document is available for free to everyone. Current revision 23.05.2025.

What is EPS Insulated Render and Where Should Fire Barriers Be Located?

Introduction to EPS Insulated Render

EPS insulated render is a widely used external wall insulation (EWI) system in the UK. In Europe, it is commonly referred to as External Thermal Insulation Composite Systems (ETICS), while in the USA and Canada, it is known as Exterior Insulation and Finish Systems (EIFS). This system consists of expanded polystyrene (EPS) insulation boards covered with a protective render coating, offering both thermal efficiency and façade protection.

EPS insulated render is preferred for many retrofit projects due to its cost-effectiveness, lightweight nature, and ease of installation. Compared to mineral wool insulation, EPS is:

More affordable and easier to install

Lighter and easier to handle

Provides similar thermal performance for the same thickness

This combination of benefits has led to its widespread use in building façades, particularly in energy efficiency upgrades and external wall refurbishments.

Fire Performance of EPS Insulation

Despite its advantages, EPS insulation is highly combustible, unlike mineral wool, which is non-combustible (Euroclass A1 to EN 13501-1).

Mineral wool insulation achieves A1 rating, meaning it does not contribute to fire spread.

EPS insulation typically achieves an E rating, indicating high flammability.

When EPS is integrated into an insulated render system, it is enclosed within protective layers, which may be non-combustible. This allows the full ETICS system to achieve a B-s1,d0 rating under the SBI (Single Burning Item) test. The SBI test (EN 13823) simulates a small fire scenario, such as a burning wastepaper basket in the corner of a room.

During the SBI test, the system is exposed to flames for 20 minutes, and the outer protective layer prevents direct ignition of the combustible EPS core. This limited testing scope has allowed EPS insulated render to be widely used on tall buildings, despite its inherent fire risks.

Fire Safety Concerns and the Role of Fire Barriers

While B-s1,d0 classification under EN 13501-1 demonstrates controlled fire behavior under laboratory conditions, EPS-based ETICS systems often fail large-scale fire tests, such as:

BS 8414 (UK standard for façade fire performance)

NFPA 285 (US standard for fire propagation in wall assemblies)

These large-scale tests are designed to replicate real-world façade fires, where EPS-based systems can contribute to rapid fire spread if additional fire protection measures are not in place.

However, building regulations in the UK and many European countries do not require large-scale testing for ETICS systems. In the UK, EPS-based insulated render systems were historically permitted on high-rise buildings under Class 0(based on BS 476-6 & BS 476-7) or as B-s1,d0 to EN 13501-1. Until recently, B-rated façade materials were allowed on buildings below 18 meters in England and Wales.

A significant regulatory issue is that ETICS systems do not have ventilated or drained cavities, meaning that cavity barriers are not legally required, which can increase the risk of uncontrolled fire spread.

Fire Barrier Recommendations for EPS Insulated Render

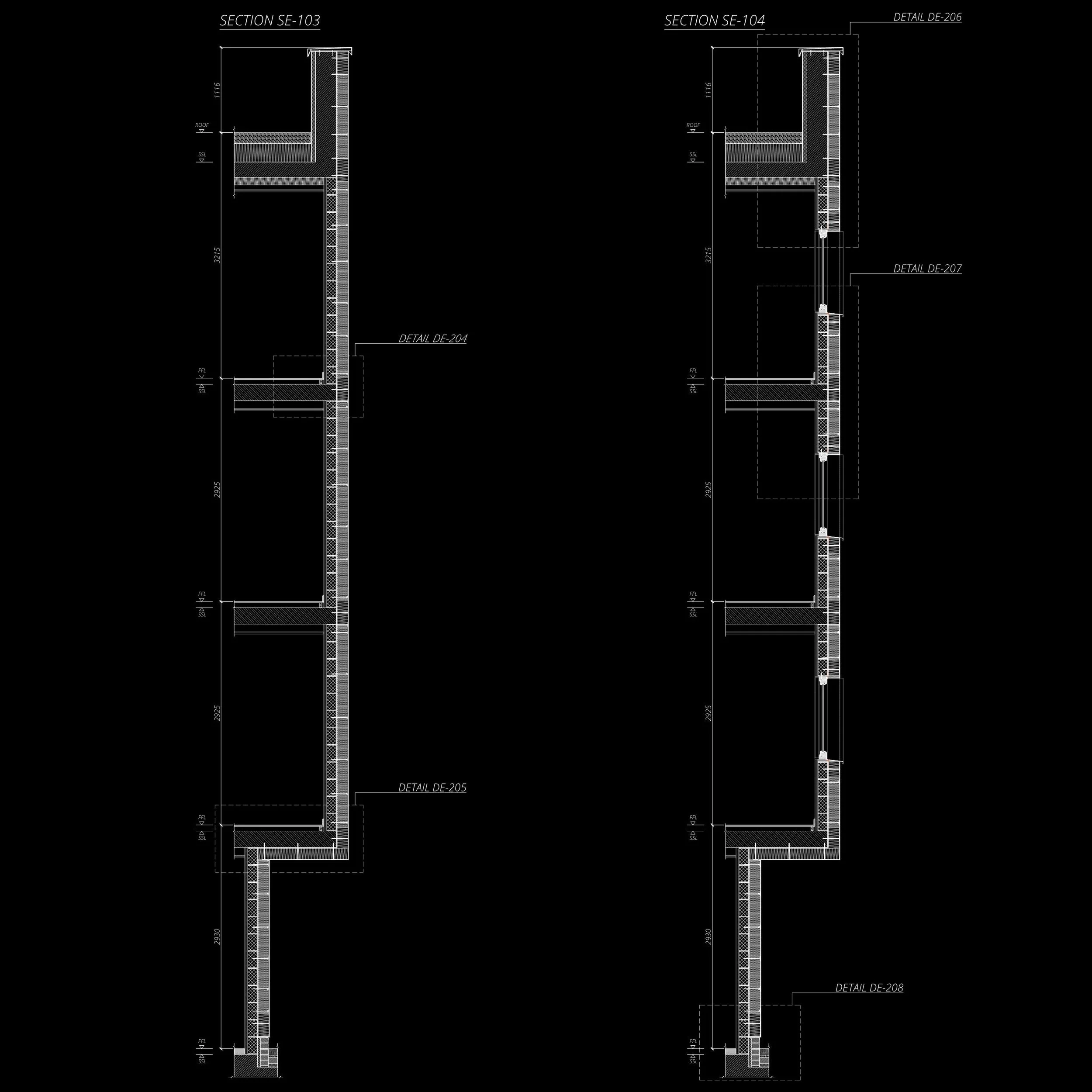

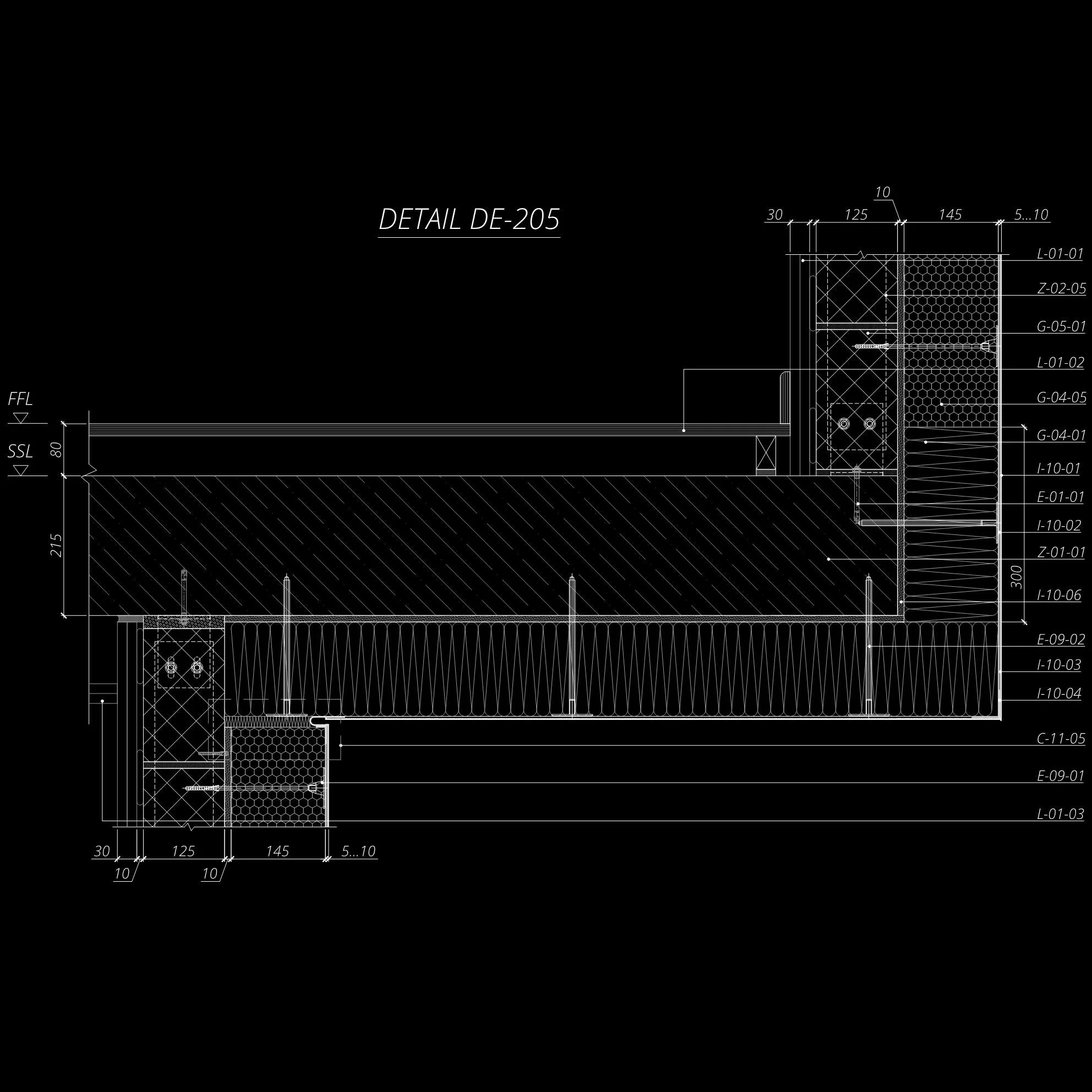

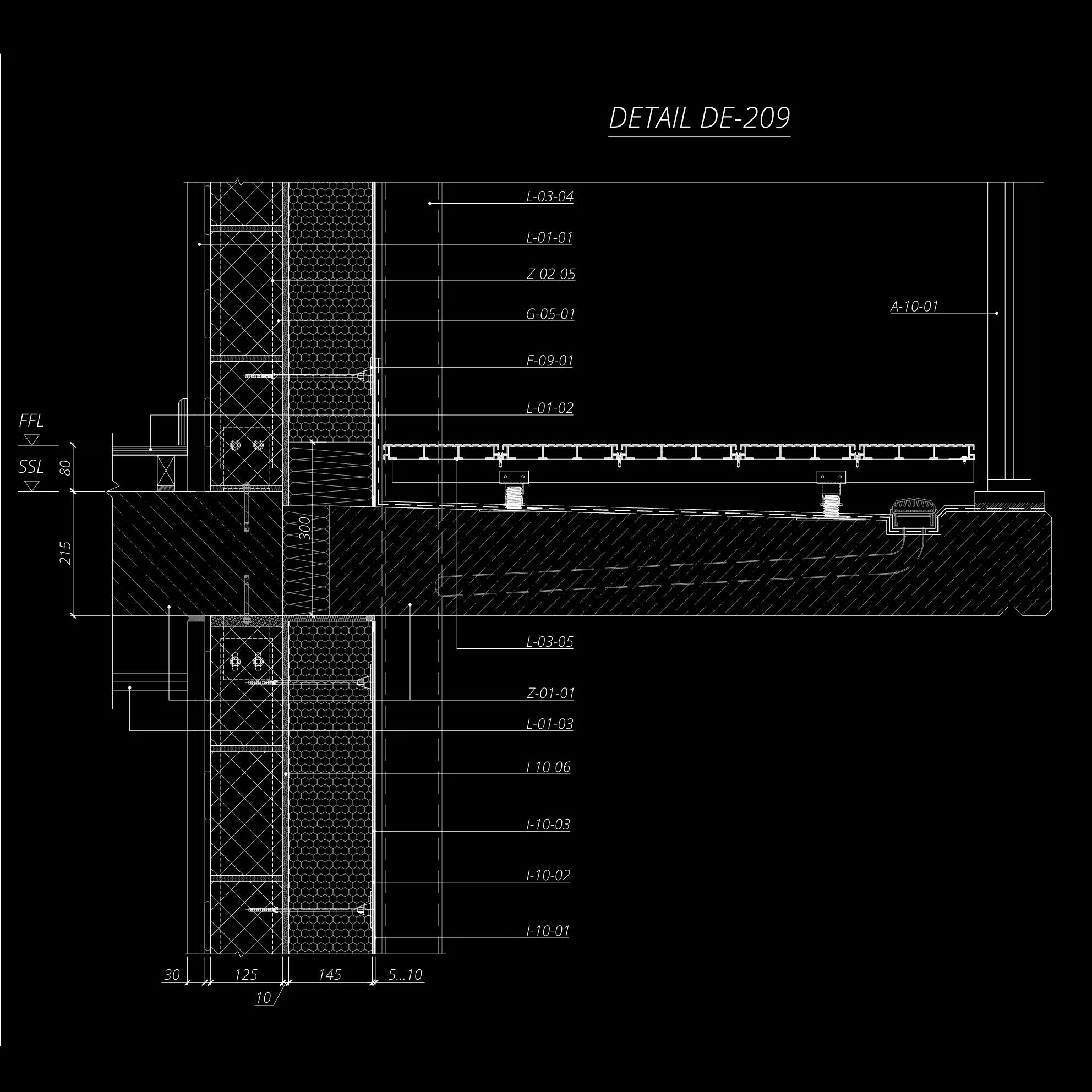

To mitigate fire risks, fire barriers should be incorporated into ETICS systems. Some ETICS manufacturers who have conducted large-scale fire tests have incorporated mineral wool fire barriers at slab levels and, in some cases, above windows.

Industry Guidelines on Fire Barriers

INCA (The Insulated Render and Cladding Association) states in its technical guide:

"Fire barriers should be installed at each floor level above the first floor (starting from the second storey)."

"Vertical fire barriers should be placed at compartment wall locations."

"Special attention should be given to openings such as windows and doors to prevent lateral fire spread."

However, there is no clear definition of what qualifies as a "vulnerable opening" or guidance on who is responsible for identifying them.

CWCT (Centre for Window and Cladding Technology) Technical Note 60 (TN60) provides general guidance on rendered cladding systems, but it is outdated (last revised in 2008).

Still references Class 0 (BS 476-6 & 7) instead of modern Euroclass ratings.

No mention of fire barriers or building height restrictions.

Suggests that large-scale tests (BS 8414-1 & 2) could be useful, but does not mandate them.

While the NHBC requires a cavity behind insulation if installed on a stud wall and specifies requirements for cavity barriers, neither NHBC nor LABC explicitly address the compartmentation of non-ventilated EPS render systems. This gap in guidance increases ambiguity in fire safety compliance.

Regulatory Gaps in Other European Countries

Our research into building codes across Europe has revealed significant gaps in fire safety regulations for EPS insulated render systems.

For example:

In Spain, according to Documento Básico SI 2019 , B-rated façade systems are permitted up to 28 meters (~9 storeys).

There is no requirement for fire barriers or large-scale fire testing.

Similar issues are present in several other European countries.

This highlights a major fire safety concern across multiple jurisdictions.

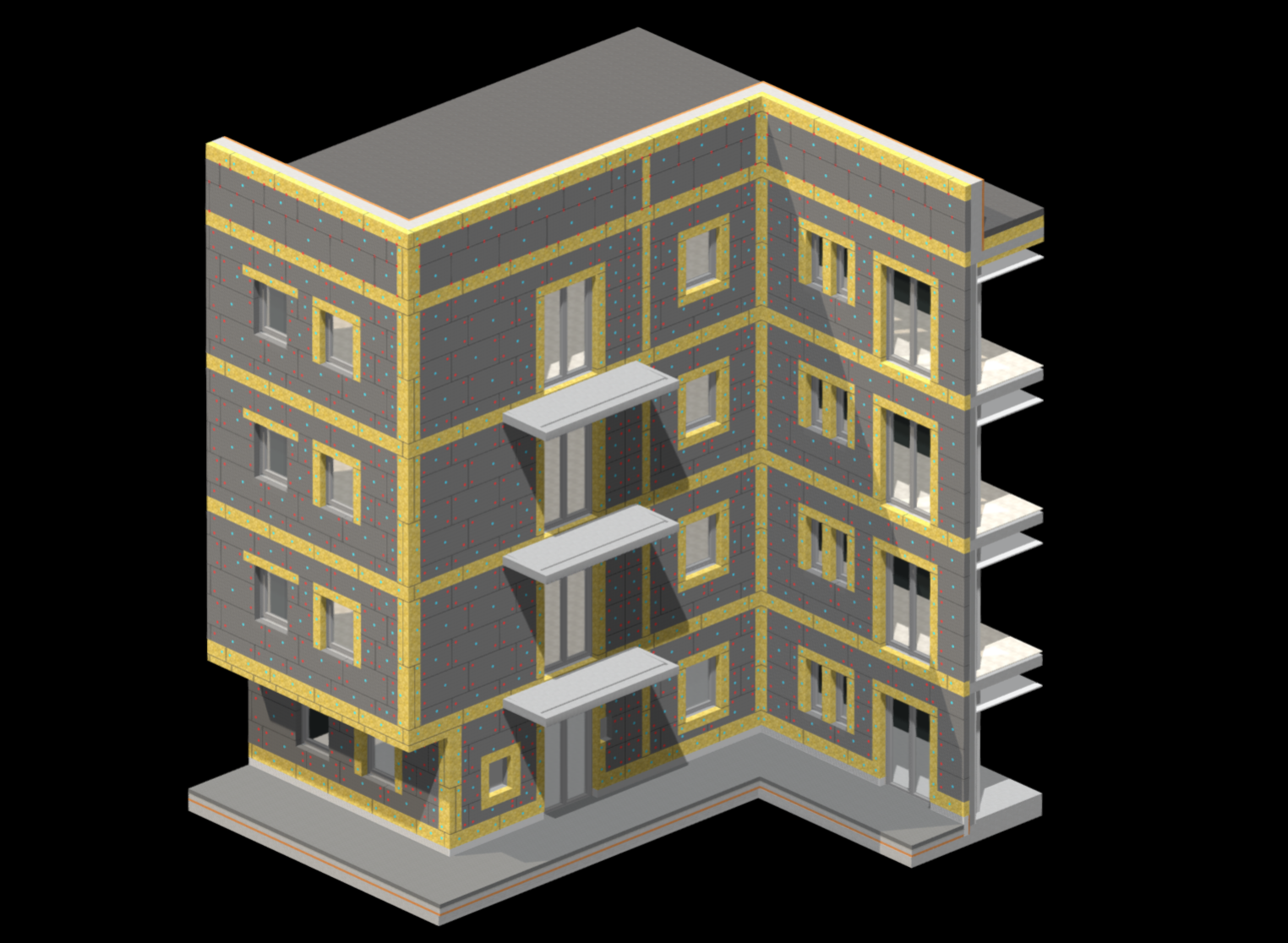

This case study is based on a 4 storey residential building containing cantilevered soffit, entrance, cantilevered thermally broken balconies, external and internal corners, various windows configuration as well as base and parapet details.

The case study goes beyond fire safety. Movement and tolerances, installation consideration, building physics considerations are addressed in this case study.

Technical review will follow, incorporating feedback from industry professionals, fire engineers, and regulatory bodies.

IAST members feedback and queries will be addressed and replied, feedback from wider public will be considered.

Multiple choice questions for Qualification Micro-credentials and CPD assessment will be prepared following technical review release.